Customization

CUSTOMIZATION

Customizable solutions

TURBINES CUSTOMIZED TO YOUR NEEDS

Each project and business case has its own individual specifics – aiming for the best possible return on investment, we provide a broad range of options and solutions to ensure that our turbines fit perfectly to such unique requirements.

Cold Climate Solutions

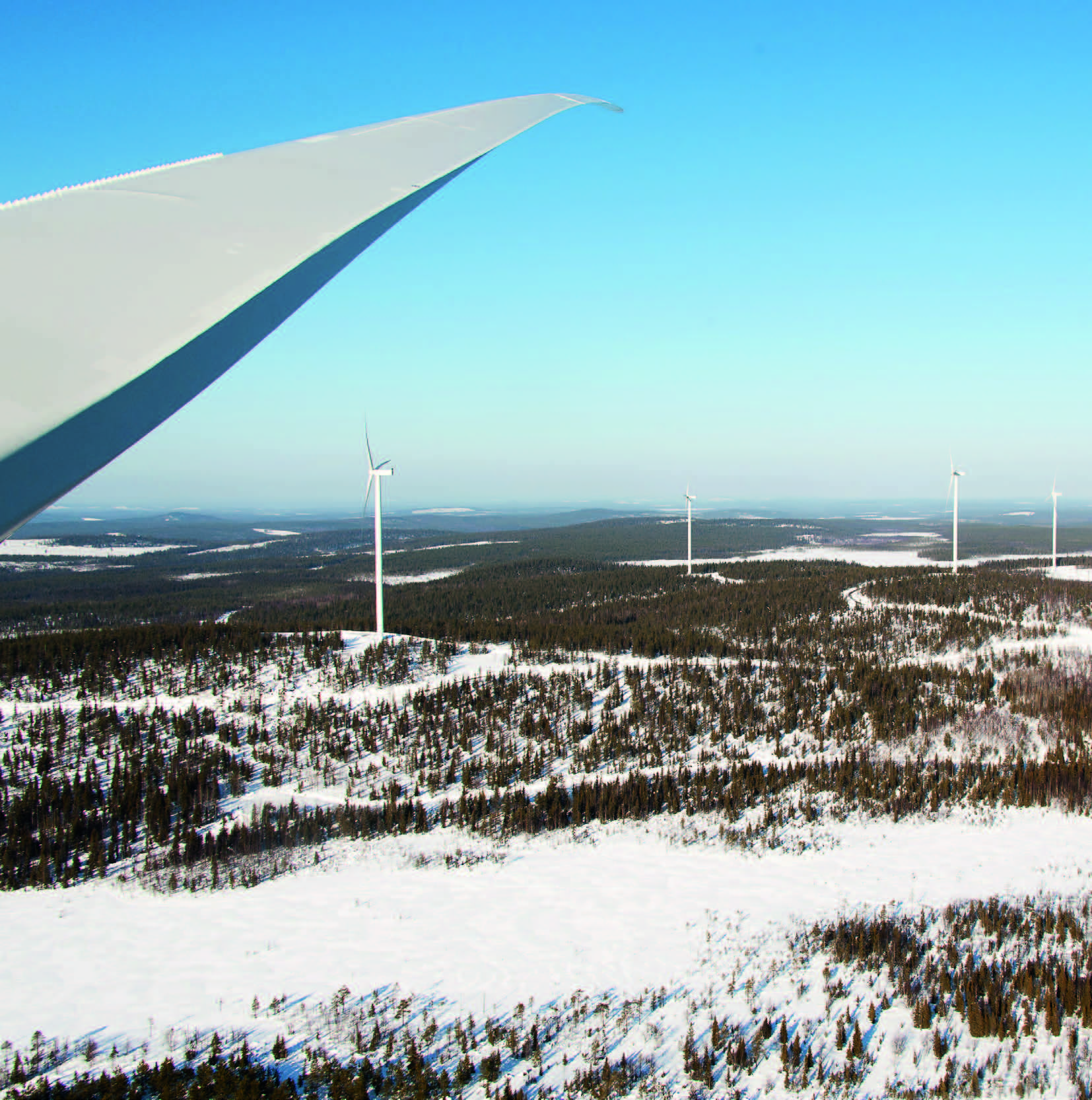

COLD CLIMATE PACKAGES & ANTI-ICING SOLUTIONS

Extended operating range down to -30 degrees Celsius

The normal climate version (NCV) of the turbine can be operated at temperatures as low as -20 degrees Celsius, thus enhancing the annual yield of your site. The proven Nordex Cold Climate Package helps to additionally open up high-yield cold locations. All turbines based on Delta4000 and Delta platforms turbines are available as Cold Climate Versions.

Advanced Anti-Icing

UP TO 80% REDUCTION OF OUTPUT LOSSES UNDER ACTIVE ICING CONDITIONS

SECURING HIGH PERFORMANCE IN ICING CONDITIONS

ADVANTAGES AT A GLANCE:

1. Heat acts on the rotor surface areas that are particularly important for turbine performance

2. Low energy consumption for all three blades of maximum 125kWh to 185kWh, depending on turbine type.

3. Up to 80 per cent reduction of output losses under active icing conditions

4. Highly robust overall system due to segmented heating elements

5. Simplified system architecture for fuss-free operation and ease of maintenance

Available for

N175/6.X

N163/6.X

N163/5.X

Tower variants

STEEL

Steel towers offer several advantages in terms of construction and dismantling. For many years, they have been the preferred technology in numerous markets due to their short assembly times. The durable and resistant material has proven itself in the field over many turbine generations. Our steel towers are conical and consist of several segments, which are transported individually to the construction site and assembled on site. Nordex offers a broad range of hub heights of up to 169 meters to optimize wind farm performance, permit applications, or to ease transport in restricted markets globally.

HYBRID

The hybrid tower is a special design for systems with hub heights of up to 200 meters. The lower section of the tower is made of concrete with the upper section of standard conical steel segments. As the concrete elements are designed to be mounted on site, hybrid towers offer advantages in terms of logistics and cost efficiency in some markets, especially for higher tower heights. Based on our comprehensive concrete and hybrid tower track record, we can offer both self-developed and supplier hybrid tower technology to our customers.

CONCRETE

The Nordex Group manufactures the precast concrete segments for concrete towers of which the company is also the proprietor of several Intellectual Property Rights regarding their design, logistics, manufacturing, and installation. These services are available at both our own and third party facilities, with the aim to always provide the most cost-efficient solution for each project worldwide.

High hub heights and maximum transportability are the main features of our self-developed hybrid towers made of concrete and steel. At the same time, the new hybrid tower solution is based on the tried-and-tested concrete tower technology that the Nordex Group has been using for over 15 years.

Customizable to fit to all sites

Adjustable solutions secure high yields on all sites

CONDITION MONITORING SYSTEM

The Condition Monitoring System allows for continuous evaluation of the main mechanical components of the wind turbine: the rotor bearing, the gearbox and the generator. Sensors analyse the performance of the wind turbine and set automatic alarms if standard limits are exceeded. This allows for immediate analysis by our diagnostics centre and enables our Service colleagues to react early before a problem results in downtime – by this, the availability of the turbine is improved and maintenance can be planned more efficiently.

The Condition Monitoring System is compatible with all Delta4000, Delta and Gamma Nordex turbines.

SERRATIONS

Sound of wind turbines highly influences their acceptance in the areas surrounding a wind park. The sound generated by wind turbines – caused by air flow around the rotor blades – can be reduced by serrations. These serrations, imitating the wings of owls, which hardly make any sound when flying, reduce the sound level by around 1.5-2.0 decibel. By attaching serrations to the trailing edge of our blades, our turbines can run in a higher operation mode with less sound, and thus, can increase AEP by up to 6 percent.

The Rotor blade serrations are available for all Nordex turbines.