Anniversary Newsletter #10: „Around the Earth, to Mars and Mercury – What Nordex turbines really deliver.”

In 2025, as we are looking back on 40 years of innovation, our turbines are proof of what is possible when engineering, vision and sustainability come together. From our Danish start-up to a global player operating on all five continents, the Nordex story is not only our company’s success story – it is also part of the global shift to renewables and a cleaner future for everyone.

Founded 1985 in Denmark, Nordex has repeatedly established itself as a pioneer in wind energy. Each new generation of turbines has been shaped by changing societal expectations, intense competition, and evolving needs of the energy market. In the end, though, what matters – then and now – is the actual power production of a turbine.

In this issue, we take a slightly different look at performance: a tour through selected Nordex Group models across four decades – from the first N27 to today’s utility-scale powerhouses.

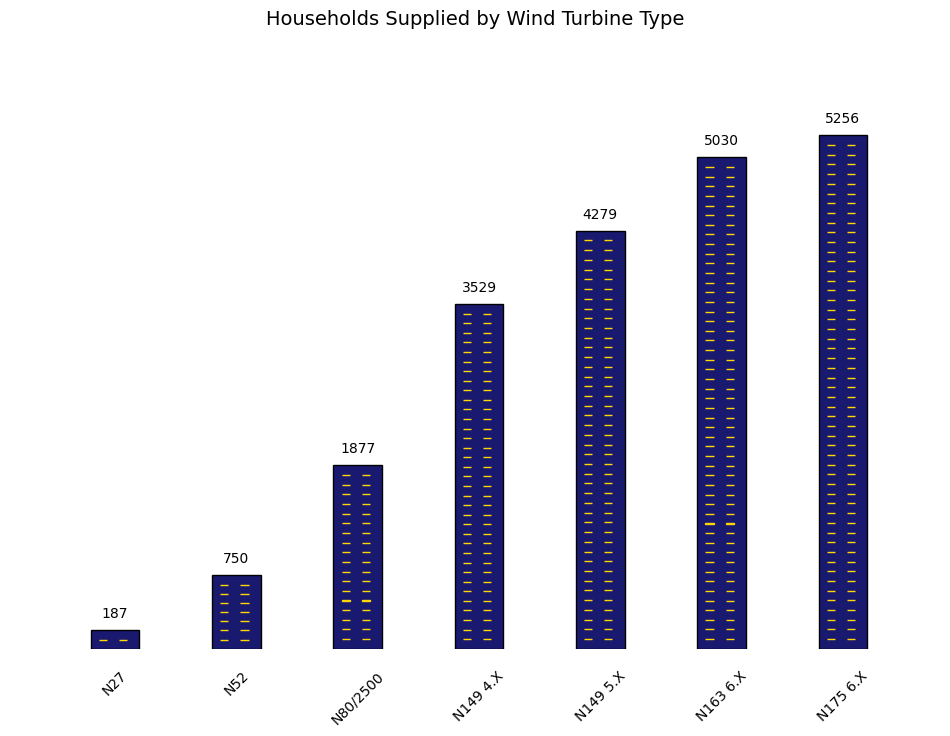

In the wind-business, a four-person household with an average annual consumption of about 3,500 kWh is often used as a reference to make a turbine’s otherwise abstract power output more tangible. A look at selected Nordex turbines over the past 40 years shows how performance has scaled: at a site with a 30% capacity factor, the first Nordex turbine, the N27, could supply nearly 190 households with clean electricity each year. The N52 later increased annual energy production to over 2.6 million kWh, serving more than 750 households. With the N80/2500, that figure rose to almost 1,900 households from the year 2000 onward. Fifteen years later, Delta and Delta4000 turbines were covering the electricity needs of more than 3,000 households, with the N149/5.X supplying over 4,200. The latest models, the N163/6.X and N175/6.X – each rated at 6,700 kW – generate over 17.6 million kWh annually, enough for more than 5,000 households. So far, so familiar.

Today we’ve chosen a new comparison: the electricity it takes to power an electric car

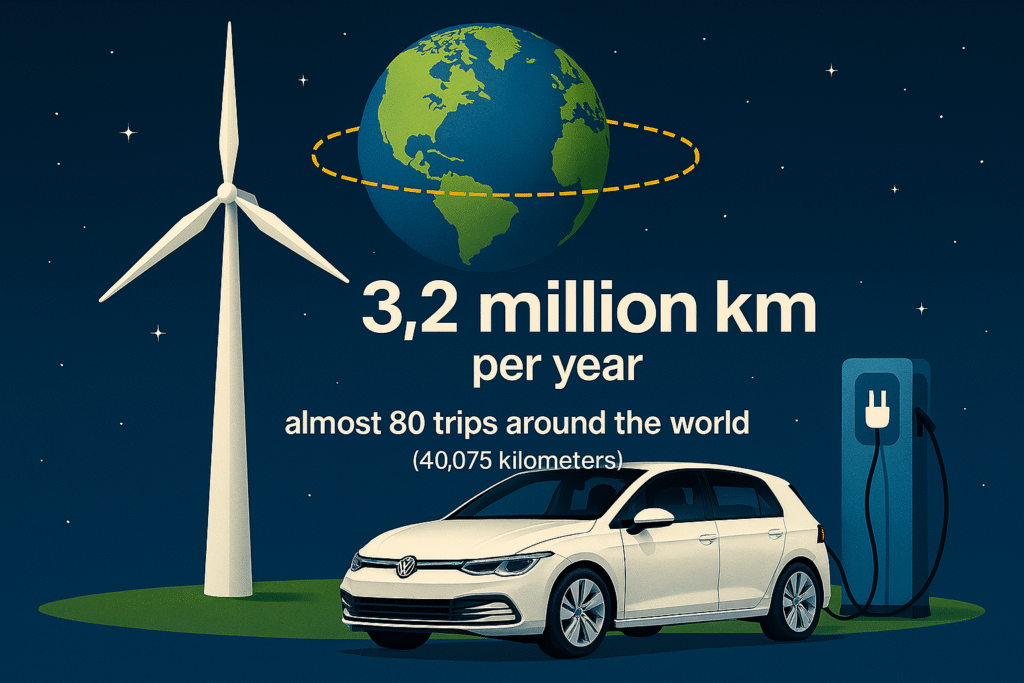

Almost 80 times around the equator in a single year …

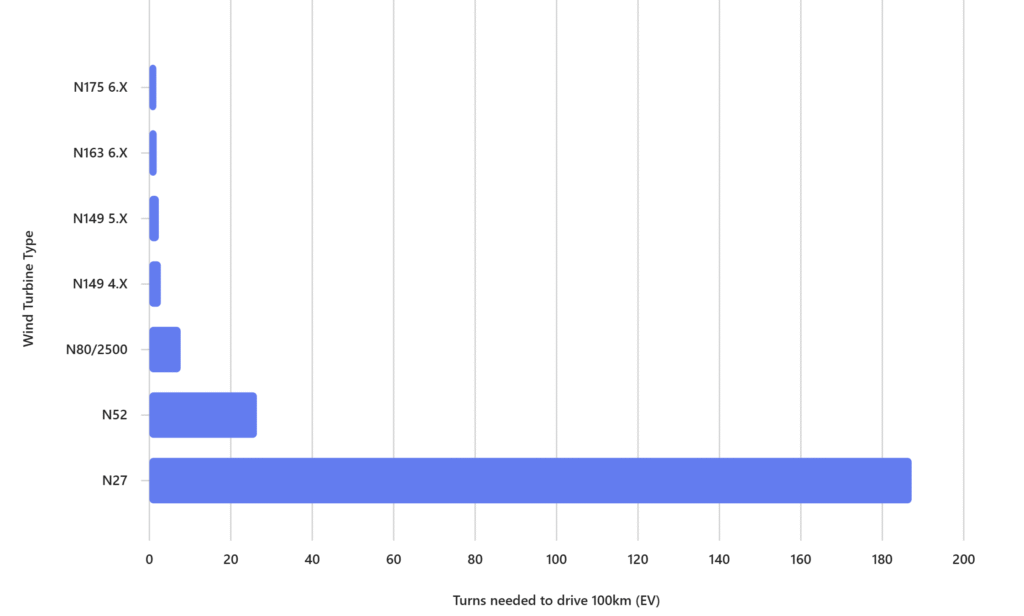

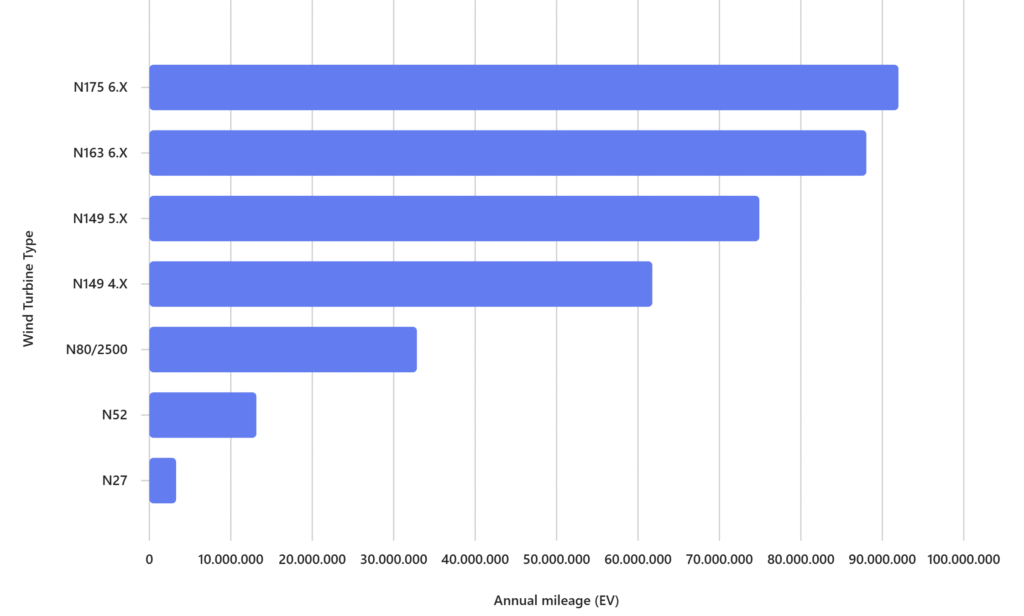

The first Nordex turbine, installed in 1986, had a rated power of 250 KW and was a breakthrough at the time: The N27 could generate around 657,000 kWh of electricity per year. Theoretically, that output would have been enough to power an electric car consuming 20 kWh/100km for more than 3.2 million kilometers – every year. That’s almost 80 trips along the equator, which measures 40,075 kilometers, in just one year.

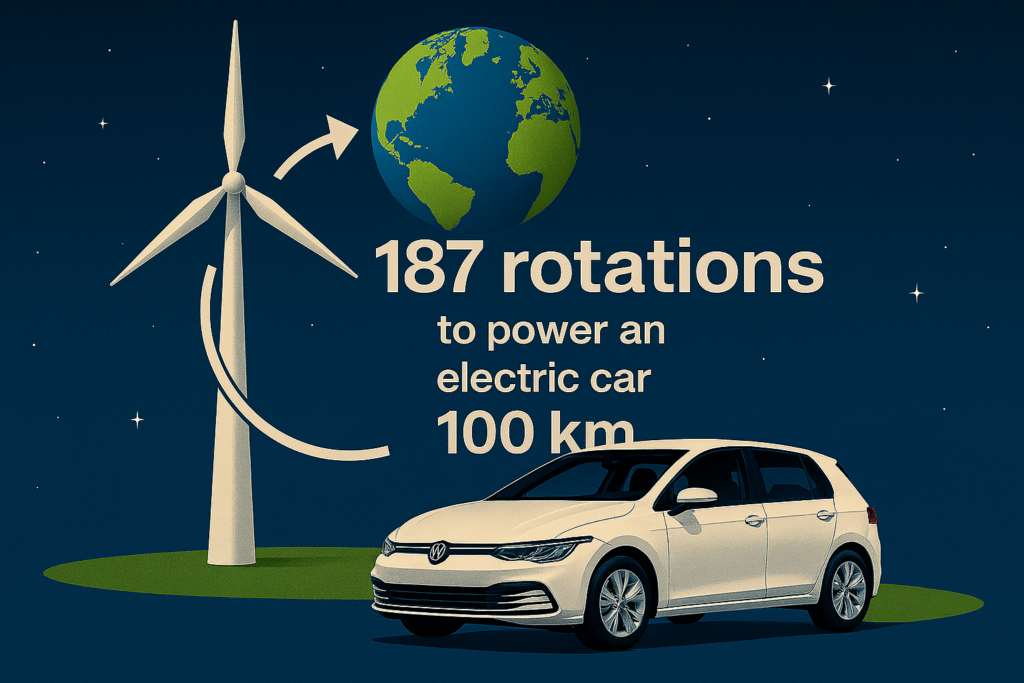

Of course, there weren’t any electric cars on the market at that time – and they wouldn’t have been able to cover that distance anyway. But if they had … And here comes a pure thought experiment: to drive 100 kilometers in such an electric car, the N27’s rotor – spinning at 39 rpm at rated power – would have had to complete 187 revolutions to generate the required electricity.

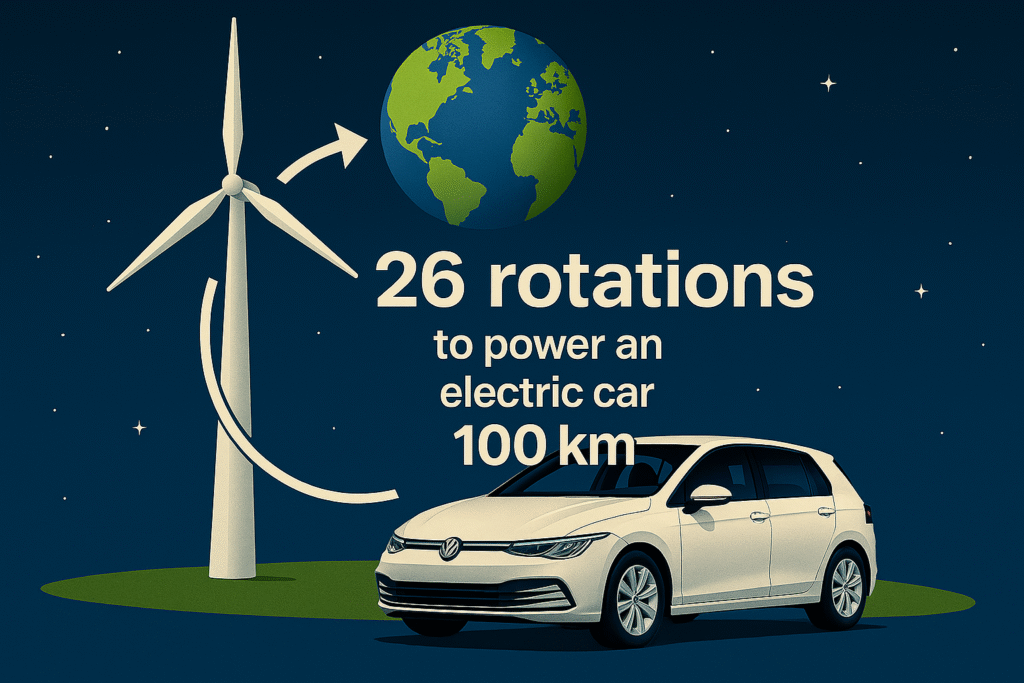

A few years later: the rotor requires one-seventh fewer rotations for the electric car to cover 100 km

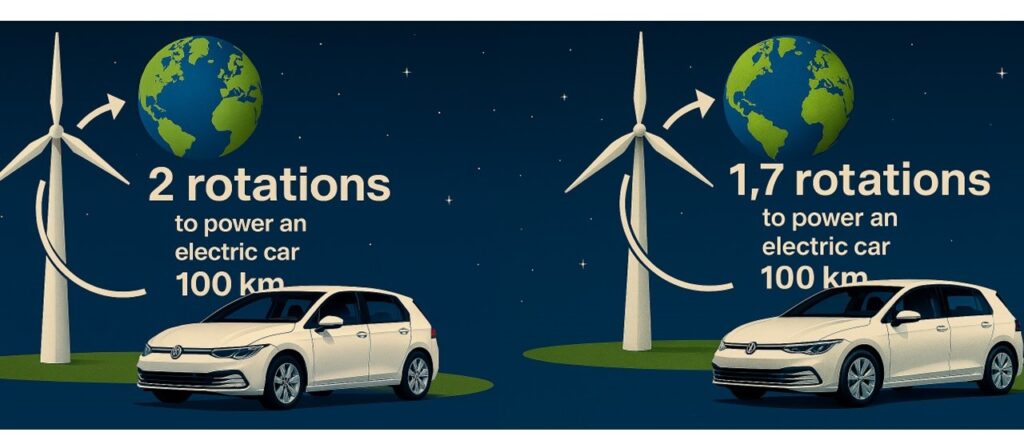

As the 1980s gave way to the 1990s, Nordex kept pushing innovation. The real breakthrough came with the N52 and N54, each rated at 1,000 kW (1 MW), marking Nordex’ entry into the megawatt era. With an annual energy yield of over 2.6 million kWh, a (still theoretical) electric car could have traveled more than 13 million kilometers per year. Now, only about 26 rotor revolutions were needed to generate the electricity for the electric car to cover 100 kilometers – around one-seventh fewer revolutions than before. This major leap in efficiency and performance set new industry benchmarks and once again positioned Nordex as a technology leader with its 1-MW platform.

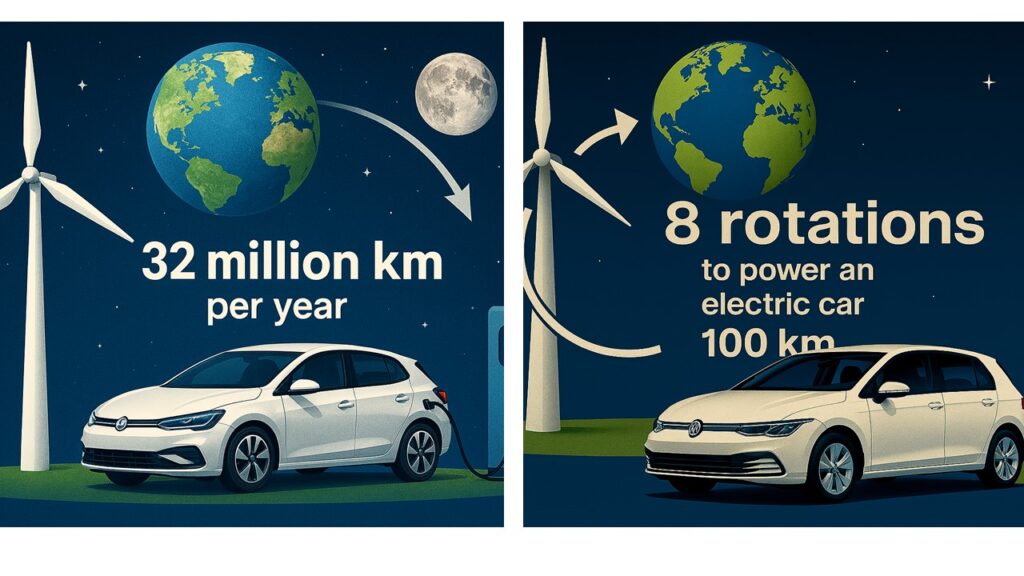

More than 40 round trips to the Moon in a year

By the late 1990s and early 2000s, Nordex was expanding worldwide and rolling out even more powerful turbines. The world’s first multi-megawatt turbine, the N80/2500, rated at 2,500 kW, could generate 6.57 million kWh annually. That output could have now driven an electric car more than 32 million kilometers in a single year. In distance terms, that’s about 83 times the average one-way Earth-Moon distance (384,400 kilometers) – in other terms, over 40 round trips per year.

And even then – 25 years ago – fewer than eight rotor revolutions were needed to generate the electricity for an electric car to cover 100 kilometers.

Mars – and more – within immediate reach

The Delta and Delta4000 series marked another major step forward in power production. The N149/4.X turbines, with rated capacities between 4,000 and 4,700 kW, can generate 10.5 to 12.4 million kWh per year. That output could now keep an electric car running for 52 to 61 million kilometers in a single year – roughly the distance to Mars at its closest approach to Earth, around 56 million kilometers.

For this turbine variant, only about three rotor revolutions are needed to generate the electricity to drive an electric car for 100 kilometers.

The N149/5.X, rated at 5,700 kW, lifts annual production to almost 15 million kWh and could keep an electric car running for just under 75 million kilometers in a single year. And yes – that’s roughly the one-way distance to Mercury at its closest approach to Earth, around 75 million kilometers. The N149/5.X’s rotor now only needs just a little over two revolutions to produce the electricity an electric car needs to cover 100 kilometers.

Only 1.7 rotor revolutions for 100 kilometers

The latest generation of Nordex turbines – such as the N163/6.X and N175/6.X – represents most advanced wind technology to date. Each is rated at 6,7000 kW and can generate over 17.6 million kWh per year. That’s enough to keep an electric car running for more than 88 million kilometers annually. At a rotor speed of 10 revolutions per minute and an energy yield of 11.2 kWh per revolution, it now takes fewer than two revolutions to generate the electricity to drive an electric car for 100 kilometers. In 7 MW mode on the N175/6.X, that’s about 1.7 revolutions.

Over our company’s history, we have not only increased the output and efficiency of our turbines, but also helped drive the shift to sustainable power generation. The arc from the N27 to the N175/6.X is emblematic: from hundreds of thousands to several tens of millions of kilowatt-hours per year, from powering dozens to several thousand households, and from the theoretical ability to move electric cars thousands to several millions of kilometers – on clean, renewable energy. The reduction in rotor revolutions needed to drive an electric car for 100 kilometers – from nearly 190 on the first turbine to fewer than two on the latest model – captures the dramatic efficiency gains and technological progress. And there’s another advantage: as rotors grow through longer blades, they turn more slowly and are perceived as calmer in the landscape. From 39 rpm on the N27 to 10 revolutions per minute on the N175/6.X – quite a step.

As electric vehicles are becoming more widespread, the electric car example offers another way to make a single wind turbine’s output tangible: in just one year, one turbine can provide the electricity for several million kilometers of electric car travel. With a service life of more than 20 years, the scale grows further – well before CO2e savings are even counted.

From 1985 to 2025, the Nordex Group’s wind-turbine evolution tells a story of continuous improvement, bold innovation, and a deep commitment to a sustainable future.

To date, the Nordex Group has sold over 80 GW of wind capacity: more than 61 GW already generating power and over 19 GW being built. The top ten markets by installed Nordex capacity are, as of today, Germany (Deutschland (8.9 GW), the United States (8.6 GW), Brasil (5 GW), Türkiye (4,8 GW), France (4 GW), Spain (3.8 GW), Finland (2.7 GW), the UK (2.1 GW), Sweden (2 GW) und Mexico (1.9 GW).

From the modest N27 to the mighty N175/6.X, every turbine has advanced our mission to turn wind into benefit – for communities and for the planet. As renewables keep accelerating worldwide, the Nordex Group is ready to keep pushing into the next era of clean, efficient, sustainable era.