Anniversary Newsletter Edition #8: “From buckets to cranes, from spreadsheets to AI-based remote maintenance – 40 Years of service at Nordex”

The story of the Nordex Group would be incomplete without a look at its service operations. In this issue, we revisit some of the key milestones in turbine maintenance and service over the past 40 years—from manually prepared Excel spreadsheets to AI-supported remote maintenance, from buckets and cranes to self-learning machines, and from a small team of dedicated people to a major division within the Nordex Group.

In the beginning, Nordex focused exclusively on developing and building wind turbines. Over time, the company’s service portfolio expanded in step with technological progress in the turbines themselves, with the service division itself driving important innovations that, in turn, advanced turbine development.

Remote monitoring and its beginnings

When the two prototypes of the N52/800 and N52/1000 were first produced in Rerik in 1995 and installed in Germany—more on this in 40 Years of Nordex Edition 7—servicing turbines looked quite different. “The turbines were, if you like, already cared for by a ‘remote monitoring system’,” says Michael Franke with a wink, then an early engineer and now VP Global Engineering of the Nordex Group. “Almost all Nordex turbines, even the first N27 models, were already connected to a telephone network and would automatically report faults. Initially, the messages were sent via modem to a PC, and later also to pagers. We Nordex employees in Rerik took turns being on call, each carrying such a mobile pager. In the event of a malfunction, the turbines would initiate a phone call that showed up on the pager. The person responsible would then connect to the turbine via computer and remote-control software to analyze and, if possible, resolve the problem remotely. If a remote solution wasn’t possible, a service team—usually consisting of us engineers—was assembled to fix the issue on-site.”

Sometimes it was also necessary to travel to the turbines, for example, if a hydraulic unit had developed a leak. Michael recalls, “Some customers would climb up onto the machine with us, while others invited us in for coffee and cake. It all felt quite like a family.” Yet this personal customer service could only be maintained for about a year: once more than 20 turbines were operating in Germany, a dedicated service department at Nordex took over these assignments for the first time.

“Back then, the turbine parameters were manually recorded using standard PCs and special software in Excel spreadsheets,” recalls Volker Bartolles, who has been with Nordex for 27 years and is now Director of Service Central.

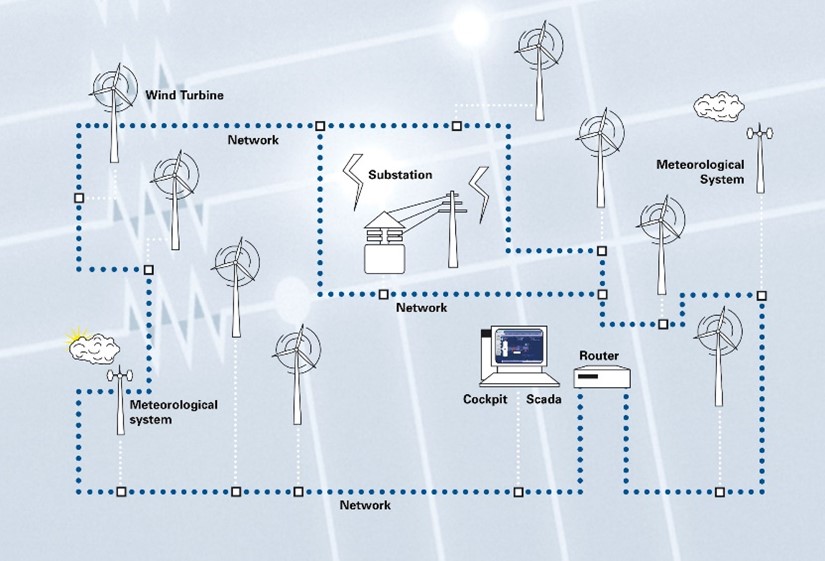

“Today, Nordex turbines are connected via the Internet, with interfaces protected by firewalls. Communication occurs not only between the turbine and the remote-control center (remote monitoring) but also at wind farm level. Underlying components—such as turbine data as well as subsystem information from converters, grid protection devices, or even the wind measurement mast—are relayed. This communication is also available to the operator and the grid operator. The grid operator controls feed-in via the interface as needed, in accordance with the current requirements of the supply network.”

From reactive operations to preventive maintenance

At the end of the 1990s, Nordex’ service approach was primarily reactive. “Service was mainly called upon for repairs, while our focus as turbine manufacturer remained on advancing turbines in line with engineering standards,” recalls Volker.

For vibration monitoring, a sensor about the size of a golf ball was installed behind the gearbox in many of the turbines at the time. If this sensor was dislodged by vibrations, the turbine stopped, and a service team was dispatched to inspect and ensure everything was in order. “Even at this stage, temperature sensors were already used on the gearbox, but washing machines of that era still proved far more complex,” Volker adds with a smile.

From the year 2000, Nordex teams began implementing preventive maintenance for the Generation Alpha and Generation Beta turbines by manually recording and analyzing relevant turbine and environmental parameters. This marked the start of a paradigm shift toward today’s predictive maintenance, which took a major step forward with the introduction of a condition monitoring system. With this system, turbine data has been systematically supplemented by additional sensor data. The kinetic data collected from the gearbox has since allowed well-founded insights into potential future material deviations. In addition, the use of video endoscopy now reliably determines the optimal timing for preventive maintenance measures.

Flexible service packages with warranties

Two years after the IPO in 2001, service received new focus in customer contract design. At that time, it often happened that service contracts were only concluded months after the turbine delivery contract—or even only after commissioning. Service was not a focus for either customers or Nordex, which is no longer the case today. In 2003, Nordex introduced its Service Suite, offering “Basic,” “Extended,” and “Premium” service contracts. With the “Premium Package,” the Service department launched an all-inclusive solution from a single source. Back then, it covered up to 12 years of full maintenance and technical operations management. For the first time, Nordex warrantied high technical availability of the wind farm throughout the contract period.

Service requirements and occupational safety have significantly shaped product development at Nordex

When repairs are necessary, spare parts must be transported up to the nacelle. In Nordex’ early years, the process quickly came to be known as “bucket work” – as on the older N27 and N29 turbines, only a rope and an ordinary bucket were available to haul spare parts up into the nacelle. It wasn’t until the 600 kW and 1000 kW class turbines that a chain hoist with a 250 kg payload was introduced, allowing parts to be lifted electrically.

Today, every turbine is equipped with a chain hoist capable of lifting 1,000 kg, along with an additional gantry crane featuring a chain hoist for moving and exchanging components within the nacelle. Moreover, the trend now is toward crane-less repairs—so-called up-tower repairs—and component exchange using a self-hoisting crane.

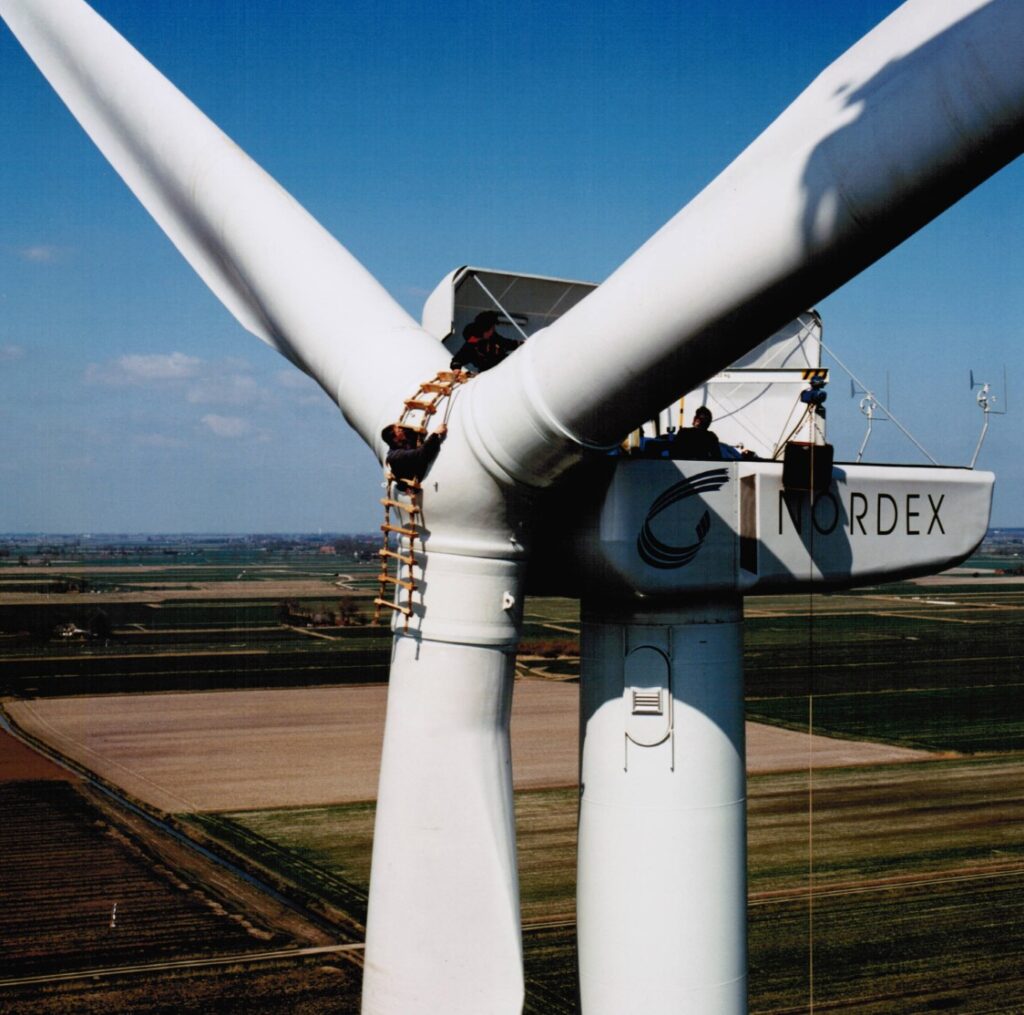

Prompted by urgent input from service staff, Nordex engineers quickly developed new solutions to ensure safe access to the interior of the turbine hub. For the N52 and N60 turbines, access to the hub was initially possible only via a rope ladder.

With Generation Alpha and Generation Beta, permanent external ladders were later introduced, providing access to a hatch at the front of the hub. In the later Nordex series, a weather-protected and safe access option became standard.

As turbine size and hub height increased, service considerations were increasingly coming into focus. For example, ergonomics for work assignments were improved by adapting walkways inside the nacelles. During the development and design of Generation Gamma, aspects like component replacement and more cost-effective repair options were taken into consideration for the first time. Access to the hub is now provided via rear manholes located between the rotor blades, rather than using ladders. This means technicians no longer need to cross the hub, which is a major advancement in terms of occupational safety.

With the introduction of the Generation Delta in 2013, service finally became a central focus in turbine development from the very beginning: Service teams actively worked hand in hand with engineers to optimize every component for ease of maintenance and cost-effectiveness. Instead of the previous rope hoists, more powerful gantry cranes were introduced, and for rapid oil filter replacement, the teams developed specialized devices. This laid the foundation for maintenance work to become even more efficient and safe. Access to the hub has since been made possible directly from the nacelle utilizing a spinner, eliminating the need for external access.

A key aspect of occupational safety also concerns the tower and access to the nacelle. Whereas in the past, technicians had to rely solely on a ladder for access, service lifts were gradually introduced from the 2000s onwards.

“Even when turbines with hub heights of 36 and 40 meters were part of the portfolio—and 50 meters were in development—one pressing question remained: ‘How are maintenance staff supposed to manage these heights, especially as they get older?’ In practice, service technicians had to cope with these challenges for several more years, since lifts only became standard with the introduction of 80-meter hub heights. At that time, this development was already long overdue,” recalls Michael.

By the time Nordex turbines reached a hub height of 80 meters, service lifts had become standard – today, no turbine is installed without one.

Service goes global

In the years following its IPO in 2001, Nordex also established its training center of excellence—for employees and customers alike. Founded in 2002, the Nordex Service Academy grew from its roots in Rostock, and later in Rerik, into a global training network.

Today, the Nordex Global Technical Academy is headquartered near the company’s main office in Hamburg. Here, a combination of theoretical instruction and practical tasks is provided. During the COVID pandemic, the training business received a boost from online courses with trainers simulating initial hands-on exercises in virtual sessions.

Since 2021, regional academies have been established worldwide. Today, the Nordex Global Technical Academy serves as a central training facility and is a certified GWO training provider for Basic Safety Training and Advanced Rescue Training.

And what does Nordex service look like today?

In recent years, the Nordex Group has regularly achieved top rankings in the service survey conducted by the German Wind Energy Association (BWE), consistently ranking first since 2021. In 2024, Nordex set a new record with a score of 2.09 points. The high quality of work and excellent responsiveness of the service teams received particular praise. Last year, new service contracts were signed worldwide for more than 8,500 MW, while 800 existing contracts were renewed—an extension rate exceeding 85 percent.

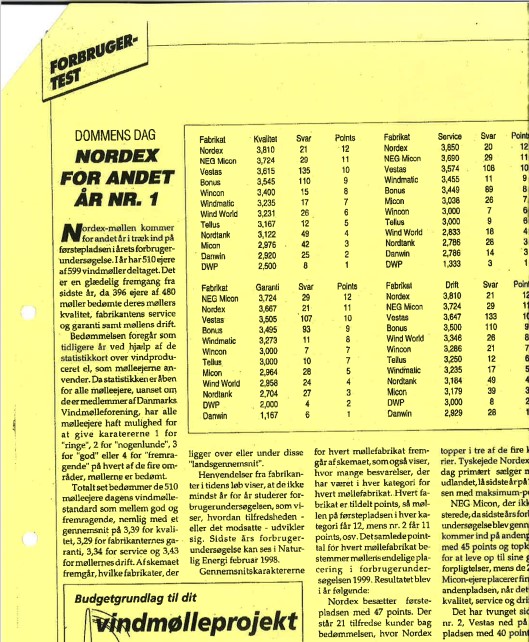

A rare find: As early as 1999, Nordex ranked first in the service survey in Denmark.

The current approach of Nordex Service involves a comprehensive assessment of turbines, incorporating both external and internal data. In particular, turbine sensor data is collected and analyzed using IoT platforms and cloud technology. As part of the “P2P – Predict To Prevent” program, state-of-the-art AI models for predictive condition monitoring are deployed. These models are developed through cross-functional collaboration between data analysts, engineers, and service technicians and are integrated into operational processes within the Service division. AI approaches such as neural networks and deep learning, combined with physical models, are used. Digital twins are trained for various turbine components to send early warnings to the service teams on site, which reduces unplanned downtime. Repairs are carefully coordinated to ensure spare parts are available and work is carried out during periods of low wind, minimizing revenue loss. The algorithms can indicate almost a year ahead whether a main bearing will fail and provide significant advantages for planning spare part availability, crane operations, and workforce deployment.

In the event of unexpected incidents, specialists at the Nordex Global Control Centre assess, analyze, and classify data from the affected turbine, aiming to resolve issues remotely whenever possible. With locations in Germany, Portugal, Spain, and India, this service is available worldwide, around the clock. Close collaboration between these sites enables seamless, cross-border support and ensures wind farms are monitored reliably and efficiently.

As a central pillar of Nordex’ service strategy, the Nordex Global Control Centre works in close collaboration with regional teams and various central functions. This ensures that recommendations from the “P2P – Predict To Prevent” program are swiftly implemented and that on-site technicians have all the information they need for the most effective service deployment.

“In the past, service technicians only intervened when there was a fault with the turbine. Later, maintenance was carried out twice a year; now, a comprehensive service once a year is sufficient. Today’s high-tech turbines are extremely complex and equipped with intelligent systems capable of detecting errors themselves. Thanks to these advanced technologies, they operate with remarkable efficiency and make work in the service sector more exciting than ever,” Volker summarizes the developments of recent years.

The future of the Nordex Group’s service lies in digitalization and sustainability. Sensors, AI-driven analytics, and remote monitoring minimize downtime. Spare part supply chains are optimized, and CO₂ emissions during maintenance operations are reduced. Currently, the Nordex Group maintains turbines with over 46 GW capacity at more than 380 service points worldwide, employing 3,800 staff. Buckets, however, are no longer primary part of their toolkit.