Anniversary Newsletter Edition #6: “40 years, 46 turbine types: Innovation in motion”

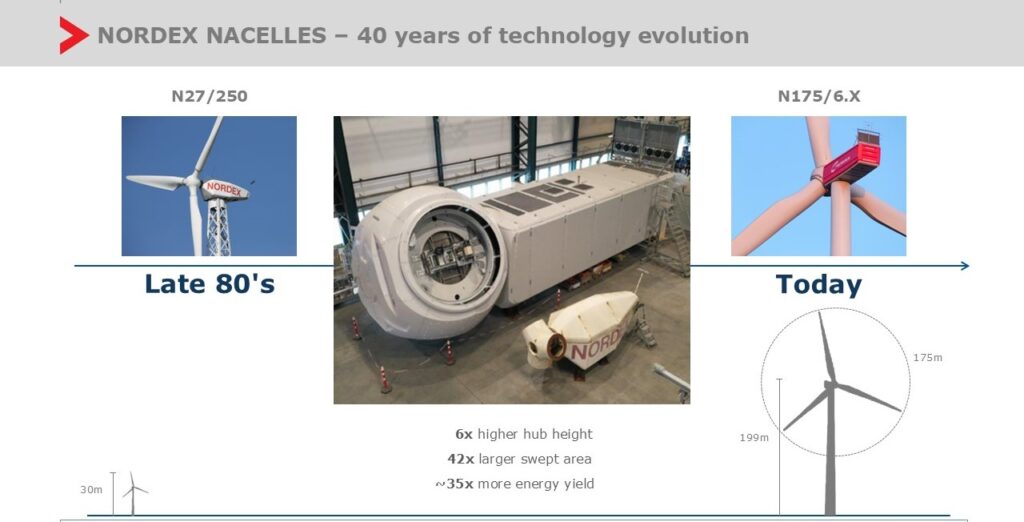

Since 1985, we have been committed to delivering the best technological solutions to meet our customers’ needs. Over the past 40 years, our engineers have tirelessly developed a wide range of turbines based on diverse concepts: more than 46 in total. – Initially created in two different companies and, since 2016 as the Nordex Group, this remarkable achievement reflects decades of innovation. Congratulations to everyone involved!

In the early days of the wind industry, it was widely assumed that increasing turbine size would lead to cost savings – mirroring trends seen in aviation. The expectation was that wind energy would follow a similar economic path. However, the cost dynamics of wind-generated electricity and energy yield proved to be quite different. Over time, the industry’s focus shifted: rather than simply boosting installed capacity, the emphasis moved toward combining larger rotor diameters with optimized nominal power and higher towers.

Join our engineers Michael Franke, VP Global Engineering and Migueltxo Núñez, Chief Technology Officer, on a journey through time as we explore key design features and platform concepts of selected onshore turbine types developed by the Nordex Group during the past 40 years. These turbines, once popular in their day, laid the groundwork – step by step – for today’s advanced Nordex Group technology. And don’t miss the test at the end.

Looking back, it might seem just a simple number: 46. That’s approximately how many different onshore turbine types Nordex Group engineers have designed and developed, project management teams have installed, and service teams have maintained over the past 40 years – not counting the various tower designs and hub height variants of each model. In other words, that’s an average of more than one turbine type introduced per year – at a minimum!

This achievement becomes even more impressive when considering the growth in rotor blade length, the rise in installed capacity from 250 kW to 7 MW, and the increase in hub height – from around 30 meters to over 179 meters today.

The first Nordex turbines – all stall-regulated machines

In the late 1980s and early 1990s, Nordex introduced its first turbines. By today’s standards, they were small – but at that time, they were impressive. These turbines featured rotor diameters of under 30 meters and a maximum power output of 250 kW. But don’t underestimate their significance: The N27/250 launched in 1987 was the largest series-produced wind turbine worldwide! (See also Edition #2 “The first Nordex-branded wind turbine”).

A few years later, Nordex expanded its rotor sizes and developed new models with rotor diameters exceeding 50 meters. The first of these, the N52/800, delivered 800 kW – more than three times the capacity of Nordex’ initial turbines. Nordex then broke new ground by introducing the N52/1000, entering the megawatt class and becoming the first company worldwide to produce megawatt-capacity turbines in series.

Did you know? At that time, Nordex also optimized the nacelle size and reduced blade length for a special model. This made it possible to ship this nacelle easily in containers perfect for overseas transport.

Take a glimpse inside the N52/1000 turbine and N60/1300 turbine designs:

The latest megawatt turbine of this class later became the technical foundation for the next generation of models – the N60/1300 and N62/1300. Over the following years, these turbines were to become Nordex’s top performers. But what did all these early Nordex turbines have in common?

Michael Franke: “Widely adopted in the 1980s and early 1990s, stall regulation was common, making the turbines simple and cost-effective. Their rotors drove generators through gearboxes connected directly to the grid without power converters. Output was regulated by aerodynamic stall. In case of errors and in high wind speeds the rotor got braked by blade tips which were released and twisted out preventing the rotor of overspeed situations.”

Apparently stall-regulated machines were quite successful at the time. By the late 1990s, Nordex co-produced a 600 kW machine, the N43/600, in China – and by 1999, it had captured 76% of the market. That same year, Nordex also completed its 1,000th wind turbine – all stall-regulated.

“But the technology also reached its limits,” continuous Franke. “The fixed-speed operation was less efficient and had poorer power regulation than later pitch-controlled systems, which are crucial for grid stability and grid compliance. Consequently, the stall concept became outdated. The N60 and N62 were the last Nordex turbines with stall control.”

You are currently viewing a placeholder content for external media from Heyzine. By clickling on “Unblock content”, you consent to content being reloaded by Heyzine. We have no influence on further data processing by Heyzine. The transfer to Heyzine may be based on the EU-U.S. Data Privacy Framework or standard contractual clauses. See further information in the privacy policy of Heyzine.

More Information

You are currently viewing a placeholder content for external media from Heyzine. By clickling on “Unblock content”, you consent to content being reloaded by Heyzine. We have no influence on further data processing by Heyzine. The transfer to Heyzine may be based on the EU-U.S. Data Privacy Framework or standard contractual clauses. See further information in the privacy policy of Heyzine.

More Information

The first 2.5 MW turbine worldwide

Rapid progress in wind technology during the 1980s and 1990s paved the way for Nordex’ multi-MW turbine. Developers believed technology was ready for a major leap, but did it live up to expectations?

“In 1999, we launched the N80/2500, the first global 2.5 MW turbine. At that point in time, we again introduced the biggest output and the biggest rotor for a series wind turbine. This Generation Alpha turbine introduced a new turbine design by Nordex that also featured a pitch-controlled system. The concept built the basis for the turbine generations to come,” explains Michael.

Pitch-controlled wind turbines use control systems to monitor power output and actively adjust blade angles to maintain safe operation. When output exceeds safe limits, the blades are pitched out of the wind and reposition once conditions normalize, optimizing energy capture. This system reduces power loss and protects the turbine from excessive torque and speed, especially in strong winds.

After 2000, Nordex’ turbine development with the N80/2500 as a starting point – followed an evolutionary rather than revolutionary path. Pitch control became standard, and Generation Beta was soon to be born.

Many modules and further developments from the Generation Beta are incorporated into various turbine types of subsequent generations.

You are currently viewing a placeholder content for external media from Heyzine. By clickling on “Unblock content”, you consent to content being reloaded by Heyzine. We have no influence on further data processing by Heyzine. The transfer to Heyzine may be based on the EU-U.S. Data Privacy Framework or standard contractual clauses. See further information in the privacy policy of Heyzine.

More Information

Südwind turbines

Years earlier, Nordex also manufactured 1.5 MW turbines under the Südwind brand, what was the reason behind this?

Michael: “The reason was to bridge the gap between our 1 MW and 2.5 MW turbines. In around 2000, a company named Südwind Energiesysteme went bankrupt and was partially acquired by Nordex, we rebranded it as Südwind Energy”.

Initially, smaller 750 kW units of the S46 turbine helped Nordex gain experience with pitch-controlled technology. Did you know? The Südwind turbines S70 and S77 – produced under license – later became some of Nordex’ most popular turbines for several years.

The concept behind the Südwind S70/1500 kW and Südwind S77/1500 based on pitch technology, built upon the successful solutions used in the sub-megawatt turbines and adapted them to meet the demands of the megawatt class.

You are currently viewing a placeholder content for external media from Heyzine. By clickling on “Unblock content”, you consent to content being reloaded by Heyzine. We have no influence on further data processing by Heyzine. The transfer to Heyzine may be based on the EU-U.S. Data Privacy Framework or standard contractual clauses. See further information in the privacy policy of Heyzine.

More Information

The Acciona Windpower fleet – AW1500

Today, many colleagues from Acciona Windpower – now part of #TeamNordex – look back on the early turbines developed there: “The first prototype – an AW60/1300 – developed by Acciona was installed in August 2000. It featured variable speed operation with a doubly fed induction generator and a medium-voltage output. The turbine was pitch-controlled using three hydraulic cylinders, and its blades measured 29 meters in length”, recalls Migueltxo Núñez. “The second prototype of AW wind turbines was a AW70/1300 with hydraulic motors. Instead of the electrical motors and batteries, we designed a pitch system with hydraulic motors and hydraulic accumulators. Nonetheless, this technology was abandoned. In 2002, a pre-series of 20 turbines was rolled out — 12 of them equipped with hydraulic cylinder pitch control and 8 with an electromechanical pitch system.”

By 2006, the first full concrete tower reaching 80 meters was erected, supporting an AW77/1500 wind turbine. This marked the foundation of the technology and experience behind today’s Nordex Group in-house developed hybrid tower, now boasting a hub height of 179 meters.

The AW 77/1300 and AW77/1500 laid the foundation for Acciona Windpower’s first turbines.

Generation Gamma and Generation Delta

From 2005 to 2015, Nordex developed new turbine types known as Generation Gamma and Generation Delta. These large turbines feature lighter components, with blade sets that weigh less relative to their length, enabling further weight savings in both nacelle and tower assemblies.

Generation Gamma

The Generation Gamma series represented the third iteration of Nordex’ 2.5 MW platform, following the Beta series introduced in 2010. So, what had been modified?

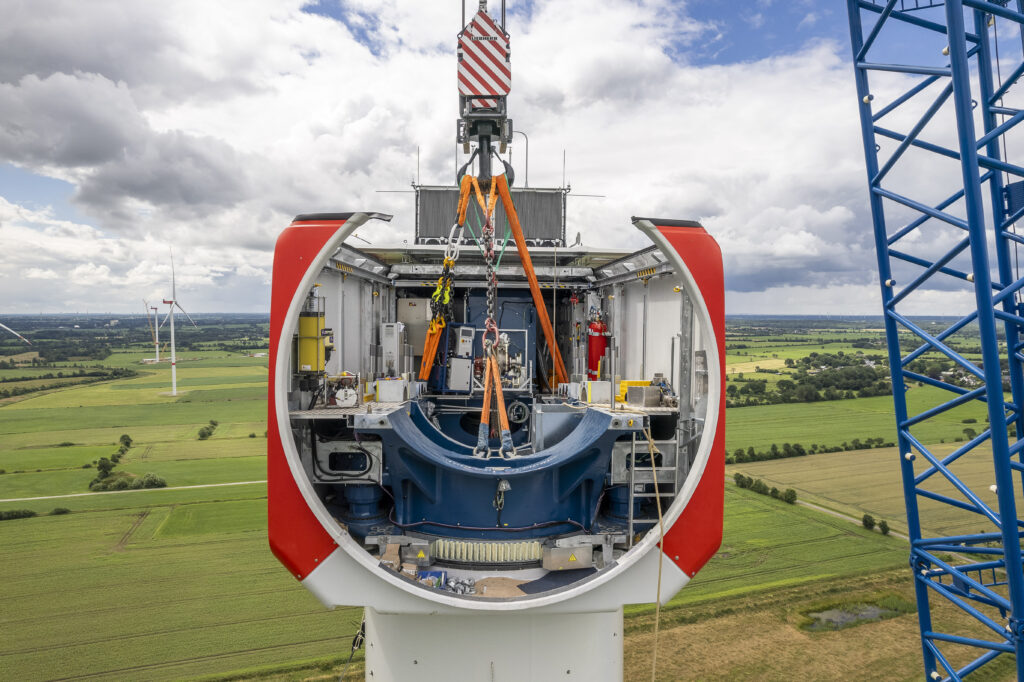

“All turbines within this series featured a modular design that enhanced maintenance and performance relative to the preceding generation. Key features included a rear hub entry, an internal gantry crane for mid-weight components up to 1000 kg, and weather-protected servicing capabilities without the need to open the nacelle roof”, says Michael.

Did you know? Introduced in 2011, the N117/2400 turbine, revolutionized the wind industry – especially for low-wind sites. Its key innovation was pairing a 117-meter rotor diameter with a 2.4 MW nominal power.

“The rotor blade for this turbine was the first one with carbon fiber girders. The Gamma platform could only be extended to 117 meters in diameter because of these relatively light blades”, explains Michael.

Afterwards, Nordex incorporated carbon fiber girders into the blades of all new turbine types – except for the later N155 model.

The 3 MW platforms

In 2013, Nordex introduced Generation Delta – an evolutionary step beyond the Gamma class. What was new?

“With Generation Delta we entered the 3 MW category. The nacelle was redesigned to offer more space and improved maintenance accessibility, featuring weather-protected direct access to the hub,” recalls Michael.

All Generation Delta turbines reflected Nordex’ strategy of adapting proven designs to specific wind conditions, while boosting efficiency and yield.

At its launch, Generation Delta comprised three turbines – all in the 3 MW class: the N100/3300, the N117/3000, and the N131/3000.

“After merging with Acciona Windpower in 2016, the Nordex Group also began marketing the AW3000 series”, adds Migueltxo. “This 3 MW platform featured up to six turbine types, starting with the AW100 and expanding to models for lower wind conditions. “

You are currently viewing a placeholder content for external media from Heyzine. By clickling on “Unblock content”, you consent to content being reloaded by Heyzine. We have no influence on further data processing by Heyzine. The transfer to Heyzine may be based on the EU-U.S. Data Privacy Framework or standard contractual clauses. See further information in the privacy policy of Heyzine.

More Information

The Delta4000 platform –flexible power output

In 2017, Nordex launched the N149/4.5 turbine, marking the start of the Delta4000 platform. Building on its predecessor, this platform not only delivered increased output but also became the first turbine worldwide to offer flexible power output.

The model N149/4.5, subsequently referred to as the N149/4.X, was launched with site-specific power options ranging from 4 to 4.5 MW.

The 5 MW class –2019: the year of three turbine types in quick succession

“In 2019, the Nordex Group launched three turbines in a row”, remembers Migueltxo. “The first one was the N149/5.X, thus also entering the 5 MW class and again with flexible output. Also, the rotor blade length played a more significant role in developing new turbine models. So, that same year, Nordex unveiled also the N155, which featured a 155-meter rotor designed for medium-wind conditions. The N155 model is now discontinued as are all former AW turbines. The N163/5.X took its seat, spinning into action with a 163-meter rotor and power settings up to 5.7 MW.”

The 6 MW class

“It didn’t take too long for the Nordex Group to then introduce the N163/6.X turbine thus now entering the 6 MW class in the year 2021, continue Michael and Migueltxo. “The turbine provides again a flexible nominal output now ranging from 6 to nearly 7 MW.”

Finally in 2022, Nordex introduced the N175/6.X, featuring newly developed single piece 85.7-meter rotor blades and a selectable capacity exceeding 6 MW. Hub heights range from 112 to 200 meters, with the first installations in Germany starting in 2024 – and in 2025 turbines reached an impressive hub height of already 179 meters.

Today

“Today, our wind turbines, with capacities ranging from 3 to 7 megawatts, include specialized models like in the future the N169/5.X for the US market and features like the Anti-Icing System for cold regions. Our advanced concrete and hybrid towers enhance our competitive product portfolio. All our turbines today are based on the developments and experience we had from the early beginnings – with success and sometimes just to say, lessons learned,” Michael and Migueltxo conclude.

Nordex’ engineers received significant recognition from the wind industry. Between 2013 and 2021 alone, the Windpower Monthly magazine awarded Nordex the coveted “Turbine of the Year” gold medal four times – for the N117, N131, N149 and N163. This is a remarkable tribute to our innovation and excellence.

Now it’s your turn to earn a gold medal – let’s test your knowledge. How quickly can you identify the turbine generation shown? Click the “link” button below to start the quiz: The image will gradually build up, piece by piece. Click the correct answer as soon as you recognize the turbine.

And if you are interested, here’s an overview of selected Nordex Group turbines: